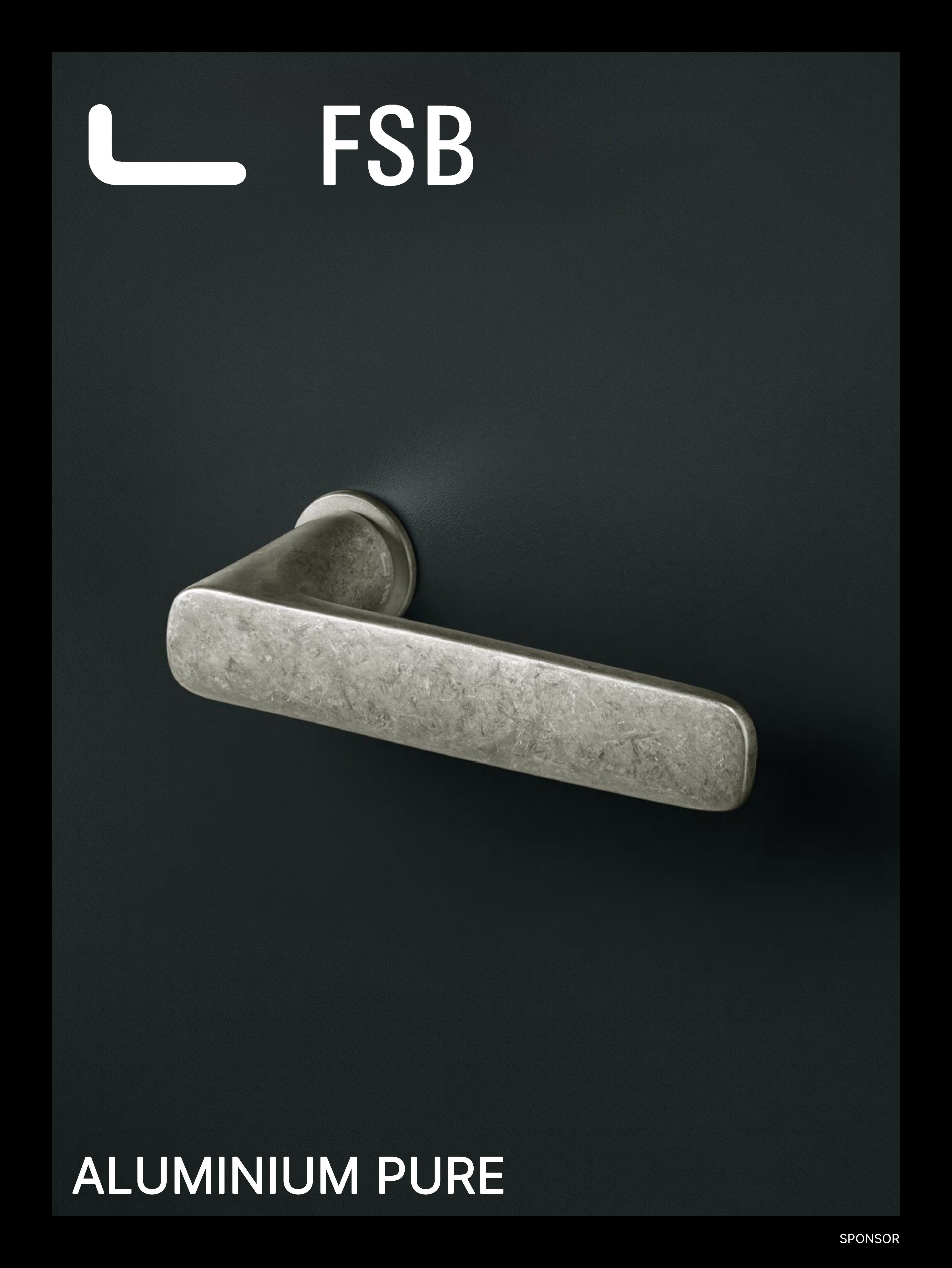

The Patina of Authenticity

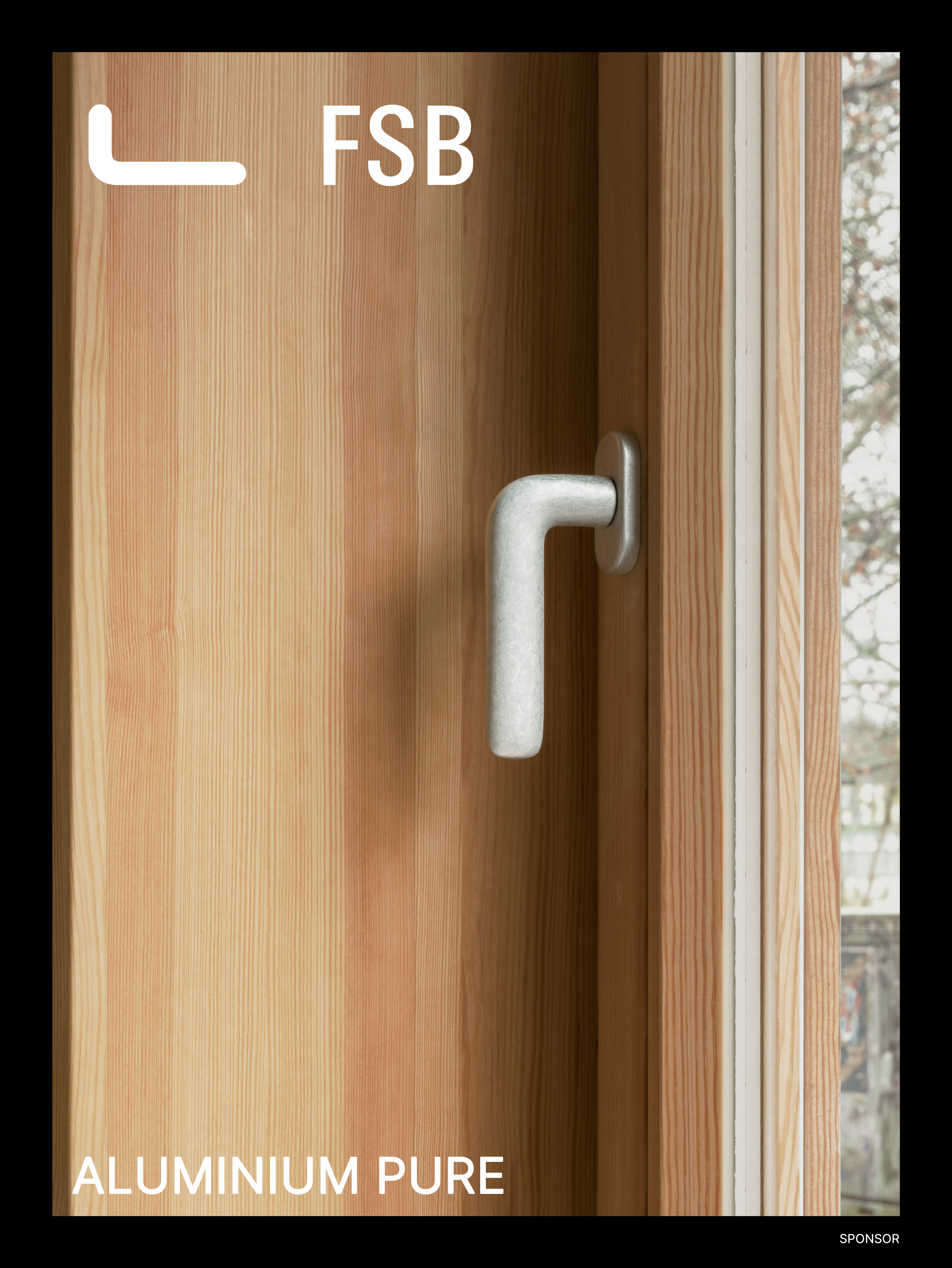

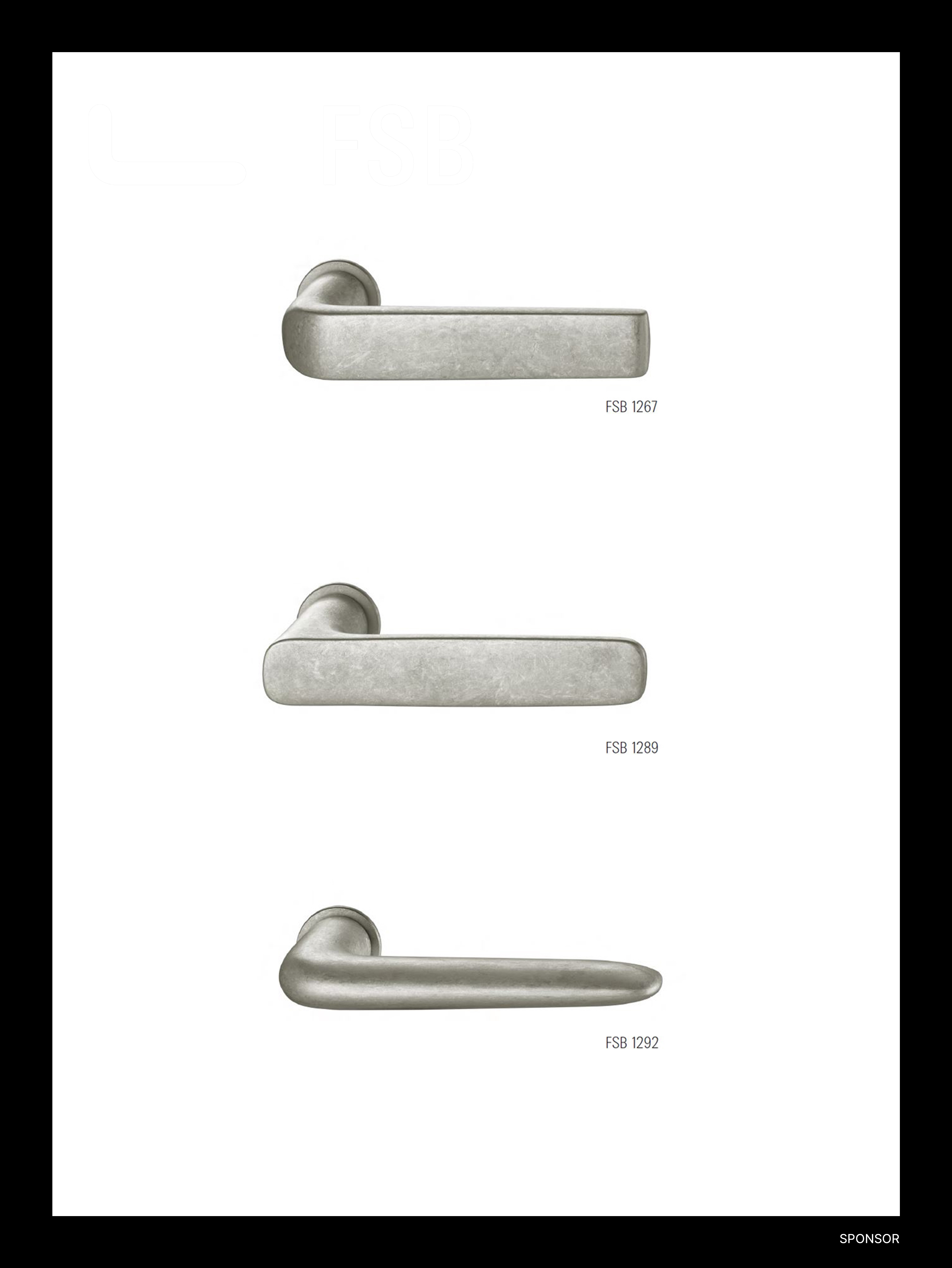

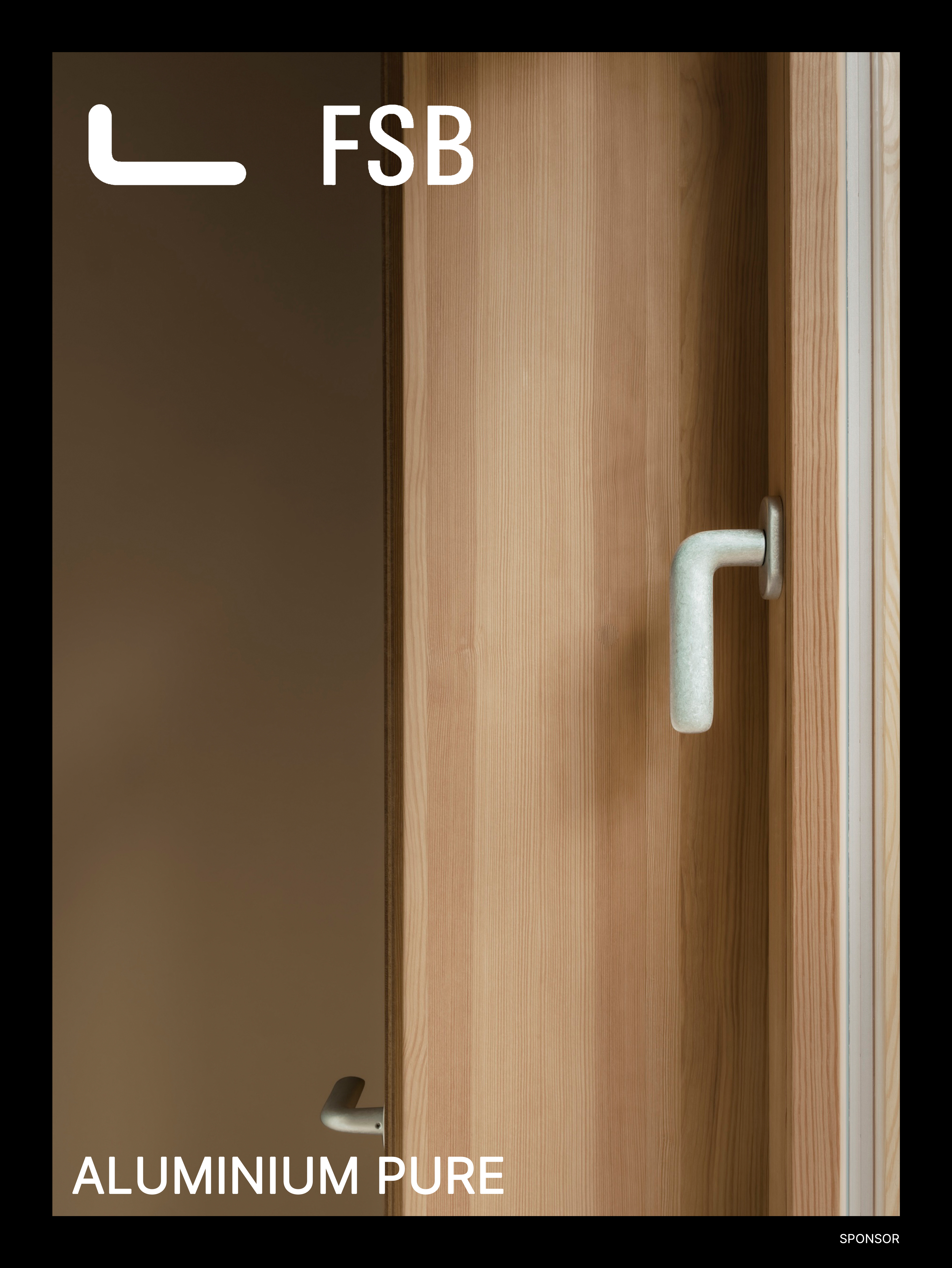

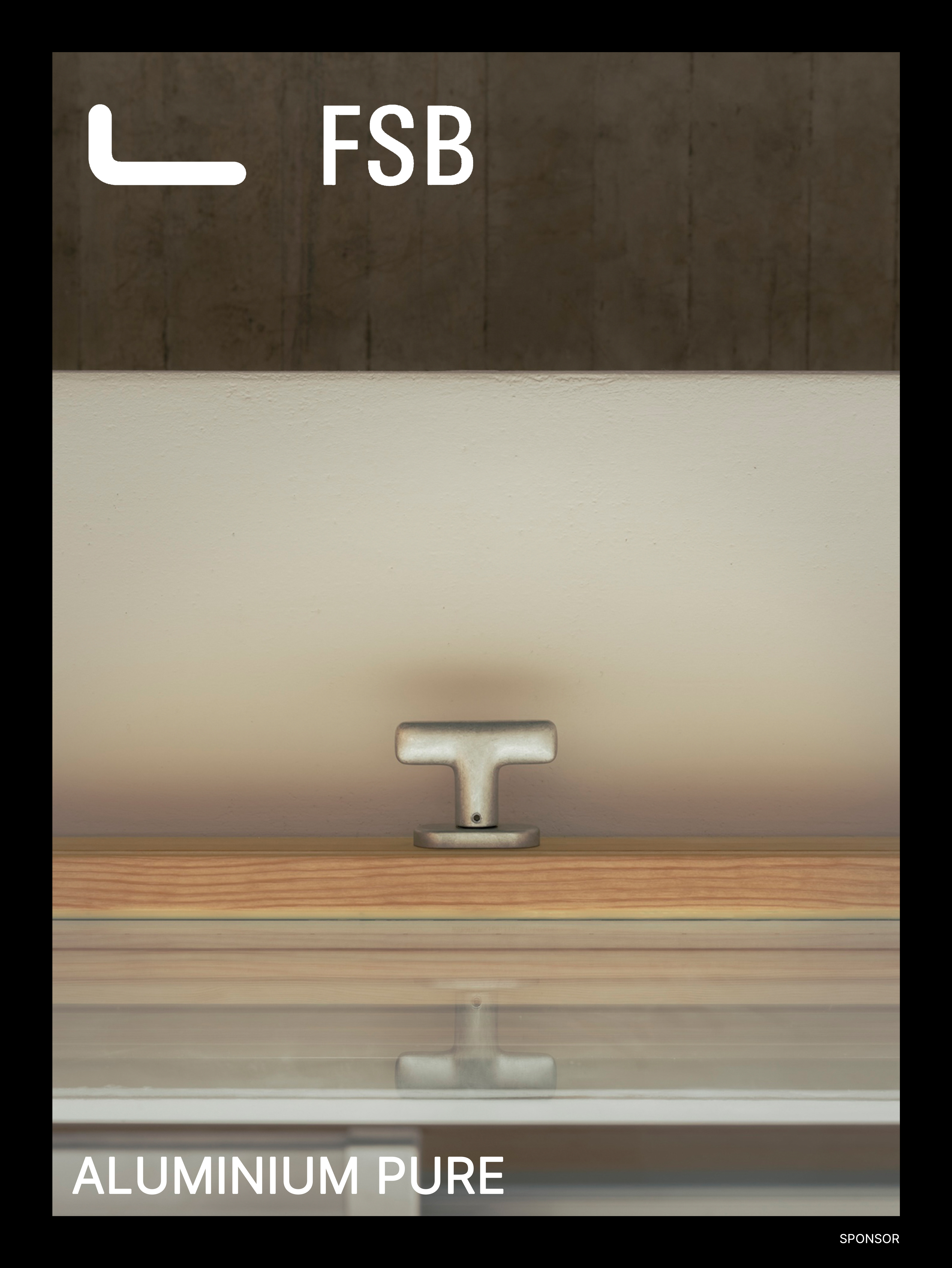

Aluminium Pure proves that sustainability and aesthetic excellence are not mutually exclusive. The virtually untreated surface develops a unique patina with daily use – a living material that tells its own story. Especially when combined with exposed concrete and natural woods, Aluminium Pure unfolds its subtle elegance. Sustainability is tangible here: compared to anodized surfaces, we save 37% energy during production.

The quality of an object is revealed not only by its utility. An equally important criterion is its lifecycle from beginning to end. For FSB, precision craftsmanship, sustainability and well-conceived design go hand in hand. From our perspective, one of the yardsticks of sustainability is long-lasting reliability. Our products demonstrably surpass the generally accepted industrial standard in both rigorous testing and everyday use.

Our hardware is manufactured exclusively from high-grade metals. FSB recognises its obligation to treat these resources responsibly and reduce its ecological footprint continuously. We have remained consistent since the early 1990s, when we were one of the first mid-sized German metal processing companies to face up to this challenge. In seeking to implement a closed-loop material cycle, we are encompassing the entire material supply chain

– from the extraction of raw materials to their processing and logistics.

The Aluminium Pure variants in the product collection warrant a special mention. The aesthetic beauty of their unique multifaceted finish serves as a visible representation of sustainability. All the aluminium we use has a footprint of 4 kg CO₂/kg – just one-quarter of the global average. With immediate effect, we are the first hardware manufacturer to offer the surface finish Aluminium Pure.

Its compelling look and feel are complemented by outstanding sustainability credentials as the customary final stages of aluminium processing are omitted. The absence of the fine dust produced by polishing or blasting and the omission of anodisation save water and electricity, and make recycling easier at the end of the products’ life. Measured against the finish 0105 (natural colour, anodised), energy consumption is an impressive 37 % lower.